|

|

This topic comprises 2 pages: 1 2

|

|

Author

|

Topic: JNIOR Redesign

|

|

|

Marcel Birgelen

Film God

Posts: 3357

From: Maastricht, Limburg, Netherlands

Registered: Feb 2012

|

posted 10-13-2017 05:52 PM

posted 10-13-2017 05:52 PM

I've used Alcorn McBride equipment for show automation in the past (they're big in the theme park market, you'll find them at the heart of many ride systems).

Both their V4 and V16 show controller are rack mountable, which I really do like. I think if you want to expand considerably beyond just "simple" cinema automation, 19" rack mountable units are a must have. They put all their I/O on the backside and I think that's the most reasonable way to roll. Unless you're building Ethernet or Voice gear, you should preferably put your I/O on the back side of things.

The only problem I have with ports on the back-side is that when you have a lot of equipment with differing heights in the same rack and one of those units is shorter and not very high (e.g. 1 or 2U), it will make those ports hard to reach.

Still, the front-side should be the "human interface" part and the back-side the machine interface. What might be useful though is a console port on the front-side. Also, if you offer something like an interactive display, make sure you can configure the network settings that way.

What I also like about the Alcorn McBridge machines is the way they connect their inputs. Instead of using cable clamps, they're using DB-9 and DB-37 connectors, which makes swapping the unit pretty easy, it also reduces the reachability issues, as it is far easier to plug in most connectors than to connect individual wires.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steve Guttag

We forgot the crackers Gromit!!!

Posts: 12814

From: Annapolis, MD

Registered: Dec 1999

|

posted 10-17-2017 04:43 PM

posted 10-17-2017 04:43 PM

I guess an advantage to that style of wiring (the KLA-1) is that one merely takes the rack panel off and dangles the unit while wiring it and then put it back so one need not leave any space to it. That said, it still has three relays for up to 5A of control, presumably 120V devices so one is routing that sort of wire in a potentially tight space. I can definitely see how some would be drawn to that style.

Thus far, for me, I've used the EPRAD eCNA-5P by treating it as a 2-part system. Mount the eCNA-5P on a low-cost rack shelf (e.g. Mid Atlantic UTR-1) and mount that at the rear of the rack/pedestal so wiring is quick/easy. It too has removable terminal blocks that are well labeled on the removable part too and the controls are connected via umbilical to a panel on the front.

The other style we've used is the eCNA-10R. This unit is rackmount BUT unlike the eCNA-5R, the 10 has the front panel flip down so one can wire/service it.

So, if you are looking to pre-package the jnior, those are the styles that would draw me to the automation.

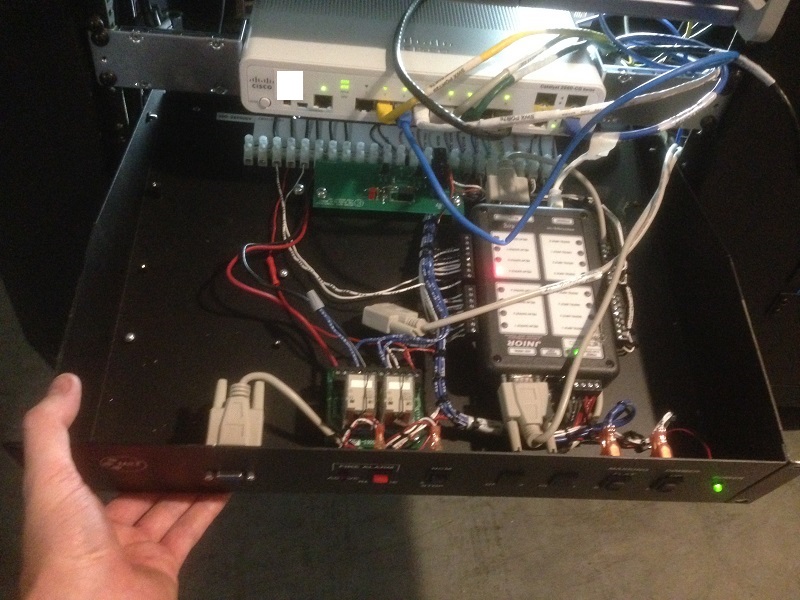

I agree with Barry that it shouldn't look like a "hack job" though I'll admit, due to the very fast pace so many of the DCinema conversions happened, things were dress a lot less than I had been accustomed in the past.

| IP: Logged

|

|

|

|

Steve Guttag

We forgot the crackers Gromit!!!

Posts: 12814

From: Annapolis, MD

Registered: Dec 1999

|

posted 10-17-2017 07:18 PM

posted 10-17-2017 07:18 PM

I think you'll find that is a factor in it. A tech is going to be influenced by the ease in which something goes in or is repaired. A support person will be influenced by what is inside (the UI, feature set and the number of calls one gets on it). The field tech and the support person may be the same person (I am) so it all goes into the mix.

I can say that I've dismissed equipment in the past due to packaging. I generally look down on things that have wall-wart power supplies too. I realize it is the easy street to UL listing but it is an outlet hungry device. In-line supplies are better but then you have to tie them up, afix them down or otherwise find a separate place for them. If one is putting the automation on a shelf, perhaps one can affix an in-line supply to the same shelf.

I can tell you that when one is putting in a complex, the more out-of-the-box ready something is the better. The more kit-like, the worse. Field time is expensive and time is always in short supply.

To use a different type of product entirely, speakers. When I started, speakers were shipped as entire kits (particularly from JBL). If you ordered a stage speaker, you got a cabinet in one box, drivers individually boxed, brackets individually boxed, horns...etc. So step one, you put it all together. It would easily quadruple installation time. Look at how QSC packages their speakers. Take the LF cabinet out, set the HF (or MF/HF) on top and screw down...done. Don't think that sort of thing doesn't influence purchasing decisions. It all goes into the cost of using something.

I guarantee you that people are choosing some servers not for their performance but for how fast the installation goes or if it can be pre-packaged in the projector. An IMS or ICMP can be installed faster than the multi-piece designs.

So back to automations, I'm sure some choices will be based on how fast/easy the installation goes, without any respect to what it does.

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 2 pages: 1 2

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic