|

|

This topic comprises 2 pages: 1 2

|

|

Author

|

Topic: Cinemeccanica Portacine Revisited

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fredrik Sandstrom

Film Handler

Posts: 63

From: Turku, Varsinais-Suomi, FINLAND

Registered: Mar 2014

|

posted 08-30-2016 02:19 AM

posted 08-30-2016 02:19 AM

quote: Ian Partridge

I have noticed that there is also an inspection hole for inching up to align with a red dot when threading so that the frame dwells in correct position with the gate aperture.

I think the purpose of the red dot is for timing the shutter with the intermittent (for example after replacing the drive belt), but sure, you can use it when threading too if you find it helpful.

quote: Ian Partridge

Following the film path to just before the sound drum, there are three tension/guide rollers. The fat middle one is static, fixed, and does not rotate ? I assume this correct and is to create a slight 'drag'to keep the film tight and smooth around the sound drum ?

Yes, that is correct, but unfortunately it does not work as well as it should. Many Portacine users (myself included) have noticed that especially polyester film will have flutter in playback. If you experience this problem, take a look at how I solved it: Portacine soundhead fix

My solution involves replacing one of the rollers with a sprocket, with an adjustable friction to provide suitable drag.

(Should my entire text be posted here for the forum archive? With or without images?)

| IP: Logged

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 2 pages: 1 2

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic

Sprung roller flange pushed apart.

Sprung roller flange pushed apart. Roller flanges together

Roller flanges together

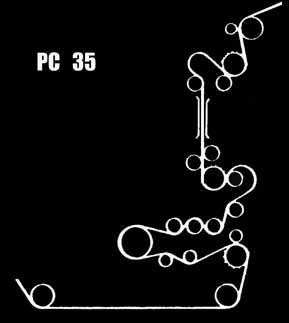

Cinemeccanica Portacine threading path diagram label.

Cinemeccanica Portacine threading path diagram label.