|

|

Home Home

Products Products

Store Store

Forum Forum

Warehouse Warehouse

Contact Us Contact Us

|

|

|

|

|

|

Author

|

Topic: Christie Failsafe

|

|

|

|

|

|

|

|

|

Ken McFall

Jedi Master Film Handler

Posts: 615

From: Haringey, London.

Registered: Apr 2001

|

posted 09-24-2002 09:04 AM

posted 09-24-2002 09:04 AM

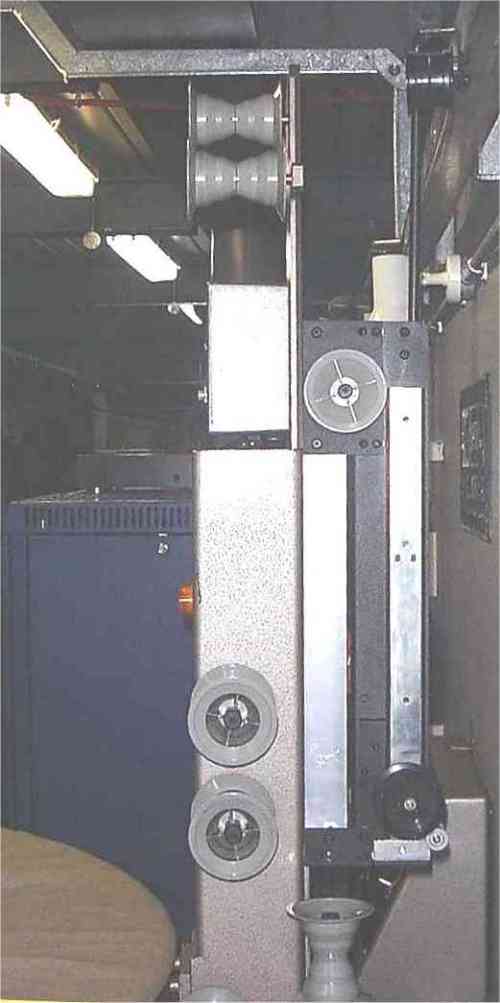

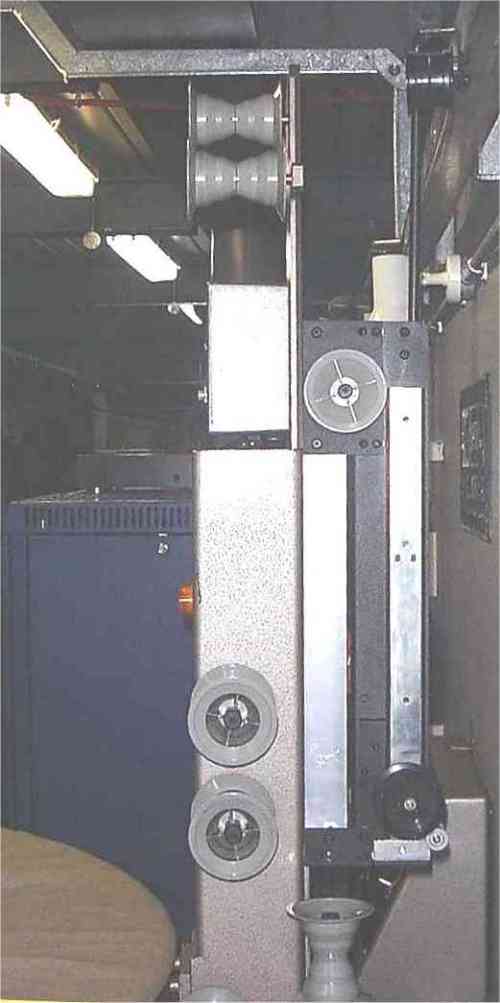

Hi German, when I needed to fit wrap sensors I hated the Kinoton version. It only had about 1 1/2 inches of travel and there was no way the film or equipment would not get damaged.So I obtained four units designed for Christie platter's, made by a guy called Nigel Shaw. I modified and fitted them to my platters in such a way that they were totally self contained with all wiring within the column. No additional connection was required to stop the projector or to the alarm system as it would ALWAYS stop the platter, the projector and switch off the xenon when running manually or on auto. This shows the sensor mounted on a 35/70 platter system. It's mounted in such a way that 35mm can be run thru the wrap sensor and 70mm over it's rollers as normal.

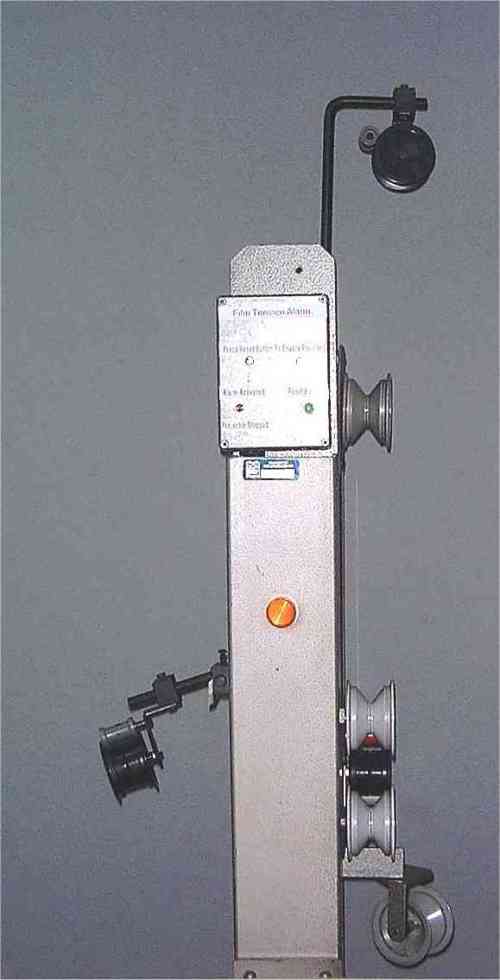

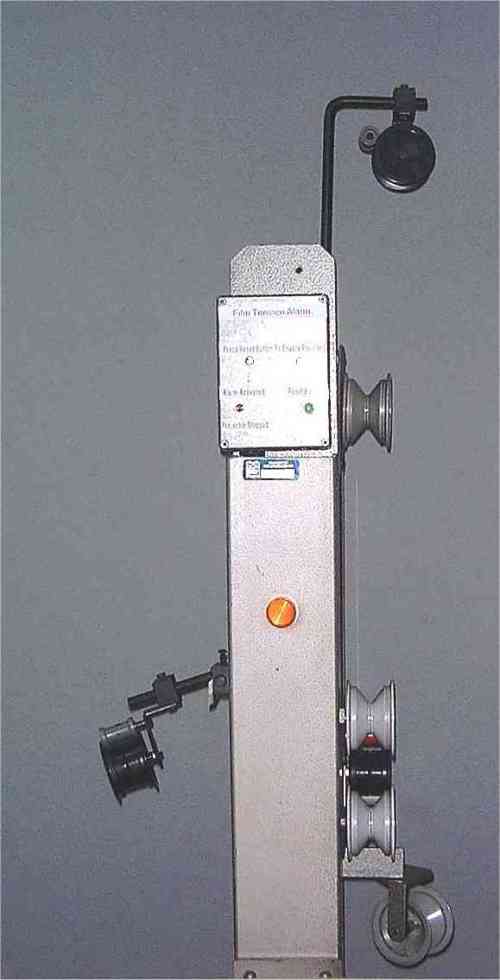

This shows a side view of the system. The film goes over the grey roller mounted in the middle of the sensor, down to the lower black roller which is mounted on the slide and then up to the diversion roller to the projector.  This shows the control box that contains a simple latching relay circuit mounted on a 35mm only platter. At the top behind is the diversion roller to supply the projector. If the film pulls the sliding roller up off it's magnet the relay latches in and stops the platter, projector and xenon. The projector cannot be started again until the wrap is cleared, the roller returned to its lowest position and the reset button pressed to release the relay. The relay will drop out if the power is turned off so it needs no 'setting up' at the start of the day. The angled black roller to the left of the column is the film return for interlock running. Film feed on interlock still goes thru the wrap sensor on every projector so we are covered every way   In normal use nothing is required of the projectionist, just turn on and lace up as normal. We have had a small number of wraps with no damage to prints at all.... the slider has enough travel to ensure there is no tension between the platter and the projector. I have run a test film on 3 screen interlock and switched projectors to manual with the alarms turned off! Gone to the first platter and held the film at the module to simulate a wrap around. It immediatly stopped the projector.... a few seconds later projector number two stopped... followed by number three. No damage and with NO alarms turned on. If the auto had been running it would have shut projectors two and three down immediatly projector one had stopped.

I've installed this system in one of our other 3 screen shows and its been very successful... all my own design, manufacture and installation, apart from the slider unit. The guy who makes the sliders now supplies me with them modified with the top extension and additional roller already mounted for me. This system works exactly as required and at the risk of sounding big headed is the best I've seen anywhere so far because it stops everything!! No chance of the platter continuing to feed film if the control arm is jammed! If anyone is interested I may make a short video of it all in action and post it..... let me know. I got a lot of satisfaction designing this system especially as no one else was able to give me what I needed off the shelf. I love it when a plan comes together

| IP: Logged

|

|

|

|

All times are Central (GMT -6:00)

|

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

|

|

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic