|

|

This topic comprises 2 pages: 1 2

|

|

Author

|

Topic: BX-60 Mystery Mount and Half-A**ed Repair

|

Jon Miller

Jedi Master Film Handler

Posts: 973

From: San Diego, CA, USA

Registered: Sep 1999

|

posted 08-06-2002 08:54 PM

posted 08-06-2002 08:54 PM

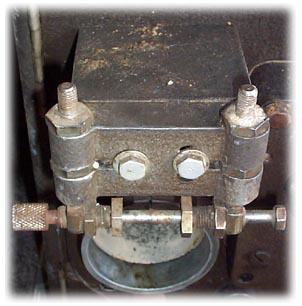

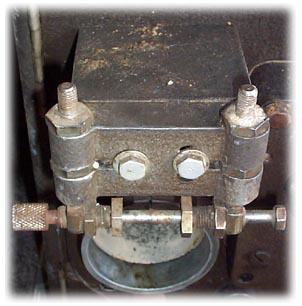

I recently acquired two Brenkert BX-60 projection heads, with RCA 9030 soundheads, Enarc lamphouses, and bases. (Yes, "say it ain't so!" Looks like once I have them cleaned up and running, I'm going to have to replace my current picture with one of me hiding behind the BX-60's door.  ) Naturally, I will have a few questions for the Brenkert-o-philes in the group...(Hello, Paul? Josh? Jeff?...) ) Naturally, I will have a few questions for the Brenkert-o-philes in the group...(Hello, Paul? Josh? Jeff?...)Both BX-60s have this micrometer-adjustable mount of some sort on the front of the head, above the lens mount.  The manual posted on this site makes no mention of this critter. Was this an attachment point for some kind of auxiliary hanger for an anamorphic adaptor, or was there some other reason for this contraption? (FWIW, these projectors were from a drive-in.) Also, one machine has a different, um, "approach" to mounting the soundhead drive gear shaft.  As this unit was the first one dismantled for transit, I thought that was the way it was mounted until I separated the second machine, which did not have this wacky bracket tacked on to a shaft that looks like one from a Super or E-7 Simplex, fastened to threaded holes tapped through the oil sump.  Is this an isolated foolish modification, or was it more common than I would think?

| IP: Logged

|

|

|

|

Josh Jones

Redhat

Posts: 1207

From: Plano, TX

Registered: Apr 2000

|

posted 08-07-2002 12:28 AM

posted 08-07-2002 12:28 AM

Dido to what Mark said. The strange drive gear mount was probably an afterthough, perhaps someone had a simplex drive assembly, but had lost the original brenkert drive assembly, and used some yankee engineering to get it to work. The BX60 was very popular for drive ins, and there are a few out there still running on their original parts. They dont make things like they used to anymore, do they?Josh ------------------

"Film is made of silver, video is made of rust"

'nuf said

| IP: Logged

|

|

Paul G. Thompson

The Weenie Man

Posts: 4718

From: Mount Vernon WA USA

Registered: Nov 2000

|

posted 08-07-2002 03:38 AM

posted 08-07-2002 03:38 AM

That's a Simplex Super of E-7 shaft. The Brenkert shaft has a flat on it so the pinning screw will keep it in place. A Brenkert shaft has no threads.That other contraption above the lens mount might be part of a mounting mechanism for a very old scope lens. I forgot if it was a Sony lens, or some Panatar lens. Oops...Mark pinpointed it. There was a set of lenses like those in Friday Harbor on Orface Island  bolted to Simplex E-7 heads. bolted to Simplex E-7 heads.

| IP: Logged

|

|

|

|

|

|

|

|

Josh Jones

Redhat

Posts: 1207

From: Plano, TX

Registered: Apr 2000

|

posted 08-07-2002 10:35 AM

posted 08-07-2002 10:35 AM

Barry,Acording to the manual, there should be an adapter plate that mates the projector with the shoundhead, very similar to the later RCA soundheads. Also supposedly, there are 4 short bolts holding that adapter plate on. If you have those four bolts out, I cant see why the two cant seem to uncouple.  Good luck, and give a yell if you need help. Josh

| IP: Logged

|

|

|

|

Jon Miller

Jedi Master Film Handler

Posts: 973

From: San Diego, CA, USA

Registered: Sep 1999

|

posted 08-07-2002 11:04 PM

posted 08-07-2002 11:04 PM

Hello, all,Thanks for all the responses! I have seen Panatar anamorphics pop up on eBay ocassionally...just didn't study those things hard enough to make note of the mounting bracket. When another one of those beasts crosses the eBay block again, I'll have to take a harder look at the picture, assuming the seller posts a good picture, of course. As far as it being a lens centering adjustment as Robert suggested, I couldn't possibly imagine it being so, since there is no direct connection to the lens barrel and no mention of the device in the BX-60 manual. John--This machine did not have a setscrew. The second machine has the setscrew, and the proper gear shaft with the flat (actually a bevel) the setscrew fastens against. (Your BX-60 modified for 4-inch lenses mounts sounds interesting...the first E-7s I laid my hands on were similarly modified...that anamorphic adaptor/prime lens combinations about the size of a two-liter soda bottle used in that machine was certainly a interesting, if unwieldy, creation.) Barry and Josh--The adaptor plate for the Motiograph soundhead is a tight fit and may have rusted in place. Maybe a little WD-40 is in order, in this particular case? Now I just have to wait for my order of ISO 10 spindle oil (and ISO 100 hydraulic oil for the soundheads) to come in, then the fun begins... --Jon (not the one taking charge of A-O-Smell  ) )

| IP: Logged

|

|

Dick Prather

Master Film Handler

Posts: 259

From: Portland, OR, USA

Registered: Feb 2002

|

posted 08-08-2002 12:20 AM

posted 08-08-2002 12:20 AM

Your mount is indeed a Super Panatar C/S lense adaptor. There is also an adjestment to center the Panatar on the screen only as well as adjustments for height and parallel. It does nothing to the back up lens. This was standard for all Super Panatars on all projectors.The soundhead drive gear shaft is the type used for Simplex. Brenkert also had a shear pin in the outer edge of the gear to the shaftto break off if something when wrong. With a part number Wolk may have the proper shaft if no one on the forum does. Aftermarket 4" lens barrel adaptors were common for drive in use to get more light. I have a Kaplan (Simplex Standard) with a 4" lens barrel. On RCA-100's you could order them either way. Should be tons of Super Panatars around. Most of them are not in use anymore. They do not work well in homes because the front glass was set up for a certain distance. Most were set for 60' to 80' and longer. Newer lenses B&L's, and others had a ring adjustment in front to set the distance for the lens. They make good paper weights. ....................................................... Motiograph soundheads an adpator plate about 4" X 10" os so long. This drops into a milled out portion on the top of the soundhead closer to the gear side. There 2 bolts in front and 2 in back. The projector is then bolted to this plate by 2 bolts. Could be rusted but when free there was some play to line up the bolts. Plate will stick out in front and back of the projector. Best of luck.

Dick

| IP: Logged

|

|

|

|

|

|

Dick Prather

Master Film Handler

Posts: 259

From: Portland, OR, USA

Registered: Feb 2002

|

posted 08-08-2002 02:42 PM

posted 08-08-2002 02:42 PM

You guys are right on about the shear pin. Don't know what I was thinking. Been too long away from Brenkerts................... Josh, The Motiograph soundhead does not have a replacable gearbox. I don't know if tou can get to the projector screws or not from below but the plate should be able to be lifted up after soaking. Maybe a slight tap of a flat chisel to get it started. I have seen both steel and aluminum plates amd most SH-7500 soundheads were also aluminum.

..................... Mark, Bob McRae is trying to get ahold of you to arrange a time to pick up some equipment you have belonging to Frank West. Please contact him.

| IP: Logged

|

|

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 2 pages: 1 2

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic

) Naturally, I will have a few questions for the Brenkert-o-philes in the group...(Hello, Paul? Josh? Jeff?...)

) Naturally, I will have a few questions for the Brenkert-o-philes in the group...(Hello, Paul? Josh? Jeff?...)

bolted to Simplex E-7 heads.

bolted to Simplex E-7 heads.