|

|

This topic comprises 3 pages: 1 2 3

|

|

Author

|

Topic: Tail Wraps

|

David Emery

Film Handler

Posts: 25

From: WI

Registered: Mar 2000

|

posted 07-29-2000 02:34 AM

posted 07-29-2000 02:34 AM

This is no joke. Has anybody ever seen or had to deal with a tail wrap ever? I have never seen one until today when one of our projectionests called me up to help fix a problem with the projector. When I got up there I saw the tail of the film was pulled into the center of the film and wrapped around the paying out film over 30 times. Luckly he cought this early before it caused dammage to the film. To pull out the mess we had to cut the payout film to untangle it from the tail of the film. Then we took the 50 feet of tail that was wraped around the payout film and straightened it out and had to place it on the floor. Then we spliced the payout film back togeather. As the projectionest started the movie the other guy had to guide the tail back on the platter and place the suction cup back on the film. Only 30 min of the film had gone though the projector when this happened. It took us about 5 min to get the film back in running shape and started again.

| IP: Logged

|

|

Mike Spaeth

Phenomenal Film Handler

Posts: 1129

From: Marietta, GA

Registered: Jul 2000

|

posted 07-29-2000 02:56 AM

posted 07-29-2000 02:56 AM

The only tail-wraps I've ever had to deal with are the ones where the tail slides off the platter and gets wrapped underneath (Speco LP-270's). Try this on for fun - the Green Mile (182 minutes) brain-wrapped, tail-wrapped, and threw itself off a set of Christie AW3's - all this w/ more than 60 minutes of film left to run. That was the worst problem I've ever seen (luckily, the booth manager of our theater was working, I was the usher manager, but it was interesting to see). Basically what happened was static electricity pulled two pieces of film through the swinging arm on the brain at once, this kicked the arm into full speed, which jerked loose the tail, and eventually, the entire print slid off the platter because of the high speed at which it was spinning.

| IP: Logged

|

|

Michael Cunningham

Expert Film Handler

Posts: 186

From: Anchorage, AK

Registered: Nov 1999

|

posted 07-29-2000 03:49 AM

posted 07-29-2000 03:49 AM

Oh yes, tail wraps are the ultimate hell of wraps. Usually, the tail comes loose from whatever retaining device you are using (suction cup, Teco pad, etc.) and the tail begins to unwind from the print as it gets slung around. When enough length has been unwound, the tail will either wrap around the arm holding up the platter or fling upward over the film paying out through the centerfeed. Either situation is a horror to fix, especially the second, but are, thankfully, easy to prevent. Just remember that no matter what size your complex is, you must visit ALL of your projectors a maximum of 15 minutes apart. If you're not almost constantly walking in circles around your booth, you're going to have trouble like this.-Mike

| IP: Logged

|

|

Leo Enticknap

Film God

Posts: 7474

From: Loma Linda, CA

Registered: Jul 2000

|

posted 07-29-2000 10:27 AM

posted 07-29-2000 10:27 AM

The way to avoid wrap hell is to use a wrap detection device. We have them for our Cinemecannica platters - they consist of a roller mounted on a vertical track (about a foot and a half tall), around which the film is laced after it comes out of the feed unit. The roller is held at the bottom of the track by a weak magnet, and there is a microswitch located about three inches up the column.If there is a very slight, brief resistance (e.g. residual joining tape causing a little bit of stickiness) then the device will absorb the shock without operating the microswitch. But if there is a very serious wrap, the roller will become detached from the magnet, rise up the column and operate the microswitch, which shuts down the whole system, raises the houselights and goes to nonsync. An alarm then rings in all the projection boxes (we have three, with a lot of stairs and corridors between each, and so cannot constantly be monitoring all our projectors) and we then go and sort the problem out. This detector has been triggered 2-3 times now and has always shut the system down before any significant damage was caused to either the film or the feed unit. Ours were supplied by a British company called Sound Associates, which also makes them for Christie platters. See www.soundassociates.co.uk. Sorry - don't know anything about US availability.

| IP: Logged

|

|

|

|

Ian Price

Phenomenal Film Handler

Posts: 1714

From: Denver, CO

Registered: Jun 99

|

posted 07-29-2000 01:35 PM

posted 07-29-2000 01:35 PM

There are two sure-fire ways to prevent tail-wraps.1. Take a scrap piece of film, wrap it around the outside of the film, tape it to itself and lable the film band as belonging to that print. Everytime the film is over, just place the film band around the print. 2. Bevan-Poo

| IP: Logged

|

|

Brad Miller

Administrator

Posts: 17775

From: Plano, TX (36.2 miles NW of Rockwall)

Registered: May 99

|

posted 07-29-2000 03:00 PM

posted 07-29-2000 03:00 PM

I've always tucked the tail and have never had any problems whatsoever, provided the platter is timed correctly, or perhaps I should say is timed the way I do it which isn't to manufacturer specs, but works far better (it's in the "tips" section) and provided there are no burrs on the platter deck's surface (buffing the platters is also in the "tips" section).I have found with un-buffed platters that have developed a glaze on the surface, the following type of tuck (inward tuck) seems to be the only way to make them stay put. Note this tuck is NOT pulled tight. If it was pulled tight, the film would have a stronger tendency to straighten out and become untucked, causing a tail wrap over the edge.

However, if the platter deck surface is not scuffed up or glazed, this type of tuck (outward tuck) is the superior method. Note this tuck IS pulled tight, for in this instance, the film will have a natural tendency to pull inward and stay put instead of flopping over the edge of the platter.

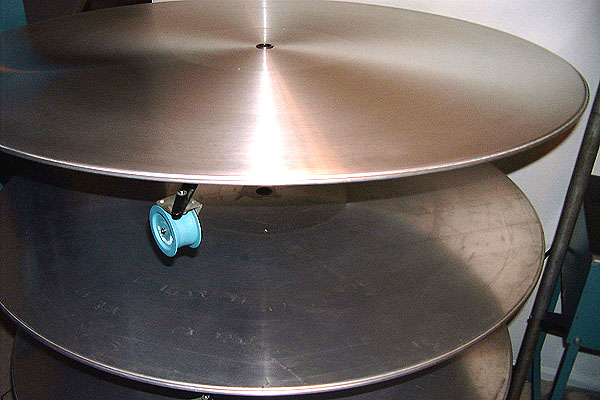

Here is what I am referring to when I say "buffed platter". Look at the middle deck in this picture. It is a platter that is less than a year old. Now look at the top deck. That is a "buffed" platter (as performed in the "tips" section of this web site) and was equally as disgusting as the middle platter before buffing. Buffing the decks places very tiny grooves in the surface, which work like grooves on a wet road to help you keep your car on the road. In this instance with even a platter timed not so perfectly, the film will stay put!

Regardless, labels should NEVER be placed on the last 5 feet of the tail. The tape makes the film too stiff and will in many cases cause the film to try to "straighten itself out", pulling the tuck. Also, labels generally have a tendency to catch on the final layers of film it is sitting under, also causing a wrap. Operators using SPECO and other platters that use "braces" underneath the platter decks must be absolutely certain they put their tucks ON TOP OF one of these braces. The decks tend to "sink" between the braces and tucks will not stay put. The picture below was simulated on a Christie, but will ONLY work on SPECO platters due to their magnetic decks. What you do is call your local pizza shop and ask for some "business card magnets". Then secure the tail like pictured below. This works ABSOLUTELY FANTASTIC on SPECO platters due to their sluggish start/stop motion.  Failing to add extra tail leader is a very bad thing for two reasons. First, the end of the credits tend to get scratched and chewed up. Second, the polyester stocks that are currently being used to print on are very stiff as opposed to acetate base film. Thus, they will act like having a label on the end of the print (but not quite as bad). This stiffer film likes to straighten itself out and once that happens, your tuck is gone. Large 1000 foot rolls of clear (or in this case white) leader without frame lines can be had for under $50 and will last an awfully long time. As an added bonus of using acetate tail leader, if those last couple of wraps of film get tangled (which is where it generally happens), the "extended acetate tail" will just break. I'm not a big fan of suction cups, Stick-A-Poos or Bevan-poos (although if you prefer to use one of these, the Bevan-poo is clearly the best). My reasoning for this is the poos are only half as tall as the film it is trying to hold! If the tail end of the film has a warp to it, it can fly right over the poo. I don't like suction cups because the suction always wears out before the feature is halfway over. Taped down, the suction cups do a good job though, but can make that platter surface not so pretty. A major problem with the poos and suction cups is if the feed arm ever swings into full throttle and the platter jumps to warp speed, it will leave the print sitting still (kind of like ripping a tablecloth out from under a table full of dishes very quickly). When this happens, poo or suction cup, you will get a tail wrap. Another big negative with poos or suction cups is if the print should get off center for any reason (generally caused by an operator pulling the center ring out by one side, thereby pushing the film slightly off center by the opposite edge of the ring), what will happen is the poos or suction cups are no longer "against" the film roll and the tail is free to fly. Film "belts" (where a loop of film is spliced together to be the same size as the outer diameter of the film roll and is then placed around the print) do work extremely well, but are a major pain to put on and take off. Also, as different platter decks take up with slightly different tension (most notable on the AW3s), the belt will need to be a different size. All in all, the simple tuck is the easiest way to go and I've ran forever with them without any problems. Just make sure your platters are timed properly and you buff your decks...then forget about it.

| IP: Logged

|

|

|

|

|

|

|

|

Randy Stankey

Film God

Posts: 6539

From: Erie, Pennsylvania

Registered: Jun 99

|

posted 07-29-2000 10:16 PM

posted 07-29-2000 10:16 PM

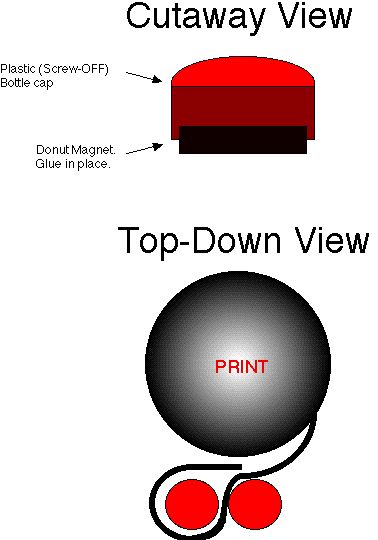

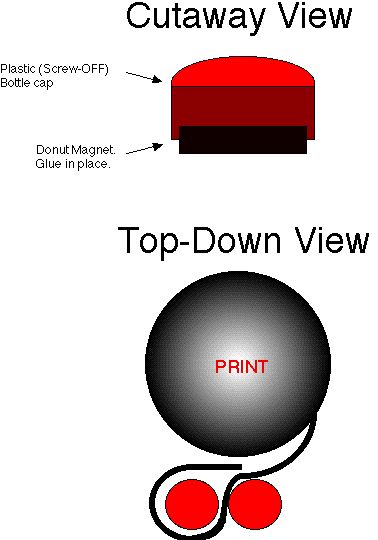

If your platter is magnetic, like SPECO, use two magnets at the tail and the film in an "S" around them.You can also make extra magnets out of (clean) plastic Coke bottle tops. (The screw-off kind from 20oz plastic bottles.)

Just get some donut magnets and glue them up inside. We have made a bunch of them.  The only caveat is that you can't push the magnets too tight together. The film has to pull free from the magnets or you they'll get pulled into the brain.

| IP: Logged

|

|

|

|

|

|

|

|

John Pytlak

Film God

Posts: 9987

From: Rochester, NY 14650-1922

Registered: Jan 2000

|

posted 08-01-2000 06:52 AM

posted 08-01-2000 06:52 AM

I agree with Brad that the condition of the platter surface and proper platter "timing" are very important in avoiding sliding rolls and "platter fling". Proper restraint of the tail lap is also critical to avoiding "tail wraps" and jams.Kelmar Systems Inc. http://www.kelmarsystems.com has developed a non-slip anti-static "platter mat". Another device that helps prevent film jams and sliding film rolls is the Non-Slip Platter Disk (patent applied for), sold by Projection Technology, Inc. (phone: 516/576-0767). This unique invention by projectionists Stuart Boritz, Edmund Nardone, and Andrew Fetherman fits on the platter surface and helps separate the film laps if they stick together, and provides a non-slip surface so the film roll doesn't slide. Other ideas were discussed in my article "Platter Patter" in the September 1999 issue of Kodak's "Film Notes for Reel People":

http://www.kodak.com/US/en/motion/newsletters/reel/september99/pointers.shtml ------------------

John P. Pytlak, Senior Technical Specialist

Worldwide Technical Services, Entertainment Imaging

Eastman Kodak Company

Research Labs, Building 69, Room 7419

Rochester, New York, 14650-1922 USA

Tel: 716-477-5325 Fax: 716-722-7243

E-Mail: john.pytlak@kodak.com

| IP: Logged

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 3 pages: 1 2 3

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic