|

|

This topic comprises 3 pages: 1 2 3

|

|

Author

|

Topic: Rebuilding an RCA 1040

|

|

|

Pete Lawrence

Expert Film Handler

Posts: 192

From: Middleburg, PA

Registered: Aug 1999

|

posted 04-11-2000 04:24 PM

posted 04-11-2000 04:24 PM

I'm also in the process of working over a pair of RCA 1040s, strictly as a hobby. Mine have a half inch of crud in all the impossible to reach places and assorted rust spots on the outside. In answer to your "can I spray the heck out of it" question, be careful. You don't want to get any cleaner or other liquid in the slit-lens optics. I'd be worried about just spraying the motor. Also, be careful of the rubber mounts that the sound optics and drum are supported by. They are oil resistant but I'm not sure about solvents. I'm doing it the hard way, complete disassembly, then clean it. If you have worked on the rubber pressure roller you have already moved the slit lens to get roller assembly out. To remove the drum you'll have to remove the prism or photocell mount, if it was converted. Once the area around the drum is clear, remove the nut on the damping flywheel, remove the flywheel and the shaft will simply pull out. There is a steel tube in between the ball bearings of the drum shaft that may fall out of position. It can be coaxed back from the backside if necessary. Or simply remove the rear ball bearing then re-assemble it. Be sure to make some notes as to what went where as you disassemble things! The manual is available on this site. So far, I have one of these monsters completely apart. I have found a few things that were obviously caused by someone not installing parts correctly in the past. I never would have found them if I hadn't taken it apart. I'd be interested to know how much Wolk gets for the roller. Also, Brad has a "fix" so the roller isn't needed and no longer touches the image area on the film. I used a larger diameter rubber tube than he suggests (not all of us have spare Kelmar parts in our tool box), but it works fine. This is a good time to ask if anyone has a spare drive gear to mate the 1040 to a simplex E7 head. I have the E7 parts but need the steel gear with the take-up pulley. Can anyone help? I'm sure there are a couple guys here that rebuild these things. Anything else we should know?

| IP: Logged

|

|

|

|

|

|

Bill Purdy

Expert Film Handler

Posts: 139

From: Seattle, WA

Registered: Oct 1999

|

posted 04-12-2000 10:02 AM

posted 04-12-2000 10:02 AM

I would strongly recommend that you replace the bearings for the sound drum. They are very commonly available motor bearings and are easy to find at bearing suppliers for two or three dollars apiece. When you start taking the shaft out, you may be able to pull it out, but there is a good chance that the old oil has glued it in place. Please, please get yourself a six to eight inch piece of hardwood dowel to use in driving that shaft out. It is also a good idea to have someone to catch it when it suddenly comes loose and wants to fly across the room. Taking the lateral guide assembly apart on an RCA is quite a trick. There is a small retaining ring buried inside that you need to know about. Also, when you polish the drum surface I would suggest that you use one of the rubberized abrasive pads that are around. Use a fine textured one so that you don't create surface that will scratch film. I ran one of these under an E7 for years with good results even though the motor ran too hot to touch. Sorry, I don't have the gear you want. One of my favorite methods for cleaning this sort of stuff is good old "Tide". Get the parts wet, sprinkle on the "Tide", wait 15 or 20 minutes, go over the nooks and crannies with a brush, and hose off. Put in a warm place so that they will dry quickly. Have fun! ------------------

Bill Purdy

Comonent Engineering

| IP: Logged

|

|

Pete Lawrence

Expert Film Handler

Posts: 192

From: Middleburg, PA

Registered: Aug 1999

|

posted 05-24-2000 11:39 PM

posted 05-24-2000 11:39 PM

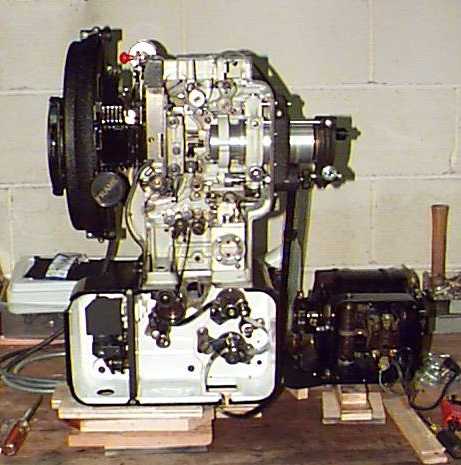

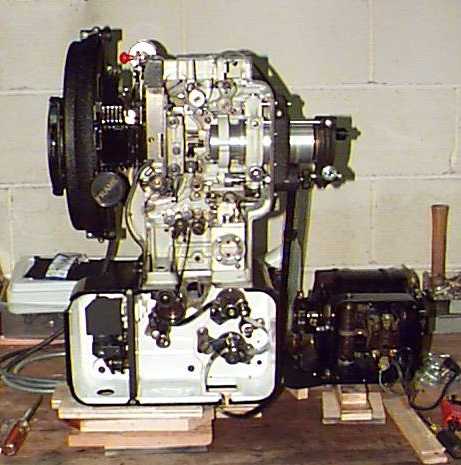

Well, it's been a very interesting project so far. I've completely rebuilt the RCA sound head. It was dis-assembled and repainted, but only required bearings, one bronze gear, and a few gaskets. The Simplex E7 sitting on top of it only required a real good cleaning and an oil change. Also, I did have to buy the drive gear that couples the two together. Two gears and the gaskets cost me more then both the sound and picture head, ouch! Thanks to Scott Norwood I now have a Simplex base. That's being repainted now. The last item I'm still lacking is the Simplex LL2 base to RCA 1040 bracket. But, I'm able to run loops with the machine "up on blocks." It purrs like a kitten. Next month I'll start cleaning up the second machine.That brings me to another question. Can anyone offer any tips on running test loops so they don't self-destruct in about 15 minutes? I want to do some scratch tests but it's hard to tell what's causing the scratches with the film rubbing on the castings. I know I need a couple more rollers. Harry, how are you doing with your machine?

"A fifty year old Simplex is newer than a six month old VCR"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Colin Wiseley

Expert Film Handler

Posts: 123

From: Blacksburg, VA

Registered: Dec 1999

|

posted 05-25-2000 11:14 AM

posted 05-25-2000 11:14 AM

Great job Pete! Pretty soon I'm going to start rebuilding an old 1040 to use with a Super Simplex film head as a functional display unit in our lobby. Will it be possible to replace the gaskets and seal up the unit so it won't leak oil on the carpet? Who's a good source for parts? Thanks!PS - Anyone out there know if Super Simplex parts are available? ------------------

Colin Wiseley

Lyric Theatre

Blacksburg, VA www.thelyric.com

|

|

|

|

Pete Lawrence

Expert Film Handler

Posts: 192

From: Middleburg, PA

Registered: Aug 1999

|

posted 05-25-2000 02:05 PM

posted 05-25-2000 02:05 PM

Thanks for the kind comments, it's been a lot of fun. And since I want to run changeovers, I get to do it all again on a second machine.  I still need a second base. I still need a second base.I'll try to answer the questions & comments in one post: Brad,

"Also, you might want to thread the soundhead so the film isn't dragging up against the front wall." Ooh, that hurt. It just looks like it's hitting in the picture. I do agreee the loop is a little to big though. Bruce,

How about some Holmes pictures? Scott,

Thanks again for the base. Mark,

I got the parts I needed from Edw. Wolk. Norm, the person there I talked to, was very helpful and was quoting part numbers for the 1040 from memory! Quite expensive though. I didn't ask him about the adapter as I didn't yet have the base. I'll ask him. This and the second good E7 and a third for parts are all oblique shaft machines. Harry,

Looks like I'm slightly ahead of you, but not for long. Colin,

The 1040 seems to be OK as to oil leaks, so far. The shafts are not "oil sealed" but do have splash shields on them and seem not to leak. The key is a new gasket for the gear box casting and the right oil level. I'm afraid the Super Simplex is designed to leak oil! On a regular Simplex head that came with my 1040's someone had installed a drip pan between the picture and sound head. It directs the oil to one corner where there was a small catch container. It's just a piece of sheet metal with the edges bent up. Looks like it might work, but your probably asking for trouble putting it directly on a carpet. Your also asking for trouble if your display machine is placed where the kids can get their fingers into it. They will!

Parts are available from Edw. Wolk and I believe from John Eickhof, although I haven't been able to catch up with John yet. Anyone know any other sources? See the Links and the For Sale forum for e-mail addresses and phone numbers, and manuals section for part numbers here.

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 3 pages: 1 2 3

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic

)

)

I still need a second base.

I still need a second base.