|

|

This topic comprises 2 pages: 1 2

|

|

Author

|

Topic: Film Cleaner Mounting

|

Randy Stankey

Film God

Posts: 6539

From: Erie, Pennsylvania

Registered: Jun 99

|

posted 01-17-2000 04:01 PM

posted 01-17-2000 04:01 PM

I've got a Potts-Alpha platter w/ Simplex Proj. I'm going to mount a film cleaner bracket to the platter. (Already have on on the proj. but I want to clean film w/o running the proj.)Anybody got any tips? Better yet, any pics of film cleaners on the platter? The instruction sheet that came w/ the bracket is pretty straightforward but you know, there's always some finer points that can only be learned from experirnce... Thanks!

Randy

| IP: Logged

|

|

|

|

Randy Stankey

Film God

Posts: 6539

From: Erie, Pennsylvania

Registered: Jun 99

|

posted 01-17-2000 04:36 PM

posted 01-17-2000 04:36 PM

So it goes on the Vert. Post facing backwards? (Parallel to the yo-yo) The instructions gave me the first impression that it went the other way. Your way makes much more sense. Maybe that's why I was so confused?What about height? Just anywhere that gives a good film path? How much room does the film need to flex between the last stationary roller on the cleaner and the payout roller/caster at the top of the tree? I figure about a foot or so... I plan to put it on the tree about even with the top platter (more or less) if I can get a good film path. If not, down near the bottom of the radical. {When I train new people, I tell them that the film on the platter looks like a giant square root symbol (proper name is 'radical'), hence "down near the bottom of the radical" means the place where the film turns the corner then goes back up to the top of the tree and out to the proj.}

| IP: Logged

|

|

|

|

|

|

|

|

|

|

|

|

|

|

John Walsh

Film God

Posts: 2490

From: Connecticut, USA, Earth, Milky Way

Registered: Oct 1999

|

posted 01-18-2000 11:05 PM

posted 01-18-2000 11:05 PM

Kelmar made film cleaner mounting brackets for V8's (also V5's and V9's). We had them on V9's about 15 years ago. They may have come out with a newer model. These were (about) a 3/8" thick, 8" x 4" aluminum plate with holes in it. You remove the upper magazine, place this plate on/through the studs and replace. Then mount the generic film cleaner bracket onto the plate.It's not a very "clean" adaption. You can't close the magazine door with it on, and you must remove the "wedge" thing that tilts the magazine forward. (If you have either of these: If you are running platters, someone has probably already removed the doors, and the "wedge" thing was usually for use with carbon lamps.) Also, Scott's right: there are four (metric, of course) bolts that are spaced much farther apart then the way American projector magazines are mounted. I'm getting on my soapbox now, so you can stop reading if you want.... I feel that the design of the V8 magazines were (hardly anyone uses magazines today) much better than almost any other projector. They could hold an hour of film (a Century JJ could only hold a 40 min reel.) The sides of the magazines were part of the door, which moved out of the way when opened, so you could get your fingers around the reel. (Not so on a Century or a AAII.) The spindles (on 70mm models) had two "locks," one to hold a 35mm reel and another for 70mm. So, you didn't have to change spindles when going to/from 35/70. Although, this meant your house reels had to be 1/2" spindles (not a problem, they cost the same), and "Reel-A-Alarms" had to be custom mounted.

(And don't say, "1/2" spindles! You can't run the reel of the feature on ship out night right on to the shipping reel with 1/2" spindles!) The firetraps could also easily be changed for emulsion in or out winds. (A AAII could also, I know.) OK, I'm getting down now.......

| IP: Logged

|

|

|

|

|

|

Randy Stankey

Film God

Posts: 6539

From: Erie, Pennsylvania

Registered: Jun 99

|

posted 01-19-2000 07:41 PM

posted 01-19-2000 07:41 PM

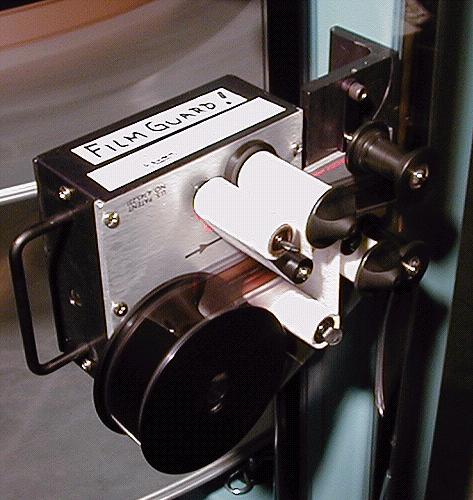

With the increased cleaning that our current film (DanceMaker) has gotten, it looks almost BRAND NEW! There's a couple of hair-line scratches here and there and that's all.With all the time and money spent on cleaning and taking care of these crummy movies, the question has been put to me, "Shouldn't somebody be paying you to do all this?" At first it was humorous. Then when the bill came, the question got serious! If you add it all up, including the cleaner, media, FilmGuard, installation labor and just the plain extra time the bill comes to over $800! For a poor little school like Mercyhurst, that's at least one, maybe two more movies we could have shown! What are the 'parameters' of getting paid? Could we 'charge-back' the company? Well, I'd probably have better luck if I wished for a pony, but at least I asked.

| IP: Logged

|

|

|

|

Randy Stankey

Film God

Posts: 6539

From: Erie, Pennsylvania

Registered: Jun 99

|

posted 01-19-2000 10:45 PM

posted 01-19-2000 10:45 PM

Well, at my "main" job, all the equipment was already in place. No extra expense. Mercyhurst, however, had to buy the stuff. Fortunately, the college President (Dr. Garvey) is a pretty cool guy. He's into the movies and he's willing to pay the bills if there's results... and there ARE results.Yup, they were emulsion scratches. FilmGuard wasn't able to remove them completely. (At least in the number of times I ran the print) However, FilmGuard WAS able to minimize them to where they weren't noticible unless you looked for them in all but the brightest scenes. I'm guessing that when the film gets scratched like that, dirt gets down into the scratch and it takes a bunch of runs to get the dirt out of the scratch before the FULL effect is noticed. You CAN see that each run minimizes the scratch a little more. I dunno. Brad's the expert on this. That's just my observations. Second... People are getting SPOILED by FilmGuard. Get this... I was asked today NOT to FilmGuard the print on the screening so that people could see what a dirty print looks like! Since we started using it (September) EVERY single run of film through our proj. has had at least one run of F.G. Nobody but me and Mike, the Work Study student, have seen dirty film! I might do it just to show them the difference. Since we got the second mounting bracket, cleaning film has been a LOT easier! We can double the number of cleanings the film gets. The picture looks even BETTER!

| IP: Logged

|

|

|

|

All times are Central (GMT -6:00)

|

This topic comprises 2 pages: 1 2

|

Powered by Infopop Corporation

UBB.classicTM

6.3.1.2

The Film-Tech Forums are designed for various members related to the cinema industry to express their opinions, viewpoints and testimonials on various products, services and events based upon speculation, personal knowledge and factual information through use, therefore all views represented here allow no liability upon the publishers of this web site and the owners of said views assume no liability for any ill will resulting from these postings. The posts made here are for educational as well as entertainment purposes and as such anyone viewing this portion of the website must accept these views as statements of the author of that opinion

and agrees to release the authors from any and all liability.

|

Home

Home

Products

Products

Store

Store

Forum

Forum

Warehouse

Warehouse

Contact Us

Contact Us

Printer-friendly view of this topic

Printer-friendly view of this topic