Strong International

Omaha, Nebraska, USA

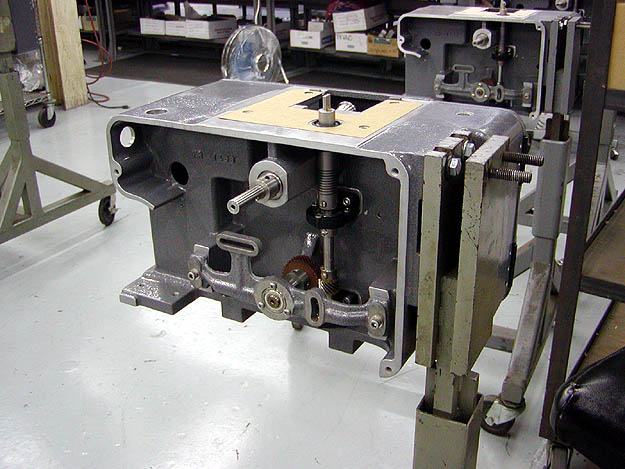

Progressively, parts are added to the naked casting.

Speaking of parts……

The century soundheads, both belt and direct drive are also manufactured on this line.

After the projector and the soundhead are built, the two are mated, waiting for shipment. The sound alignments are also performed at customer request.

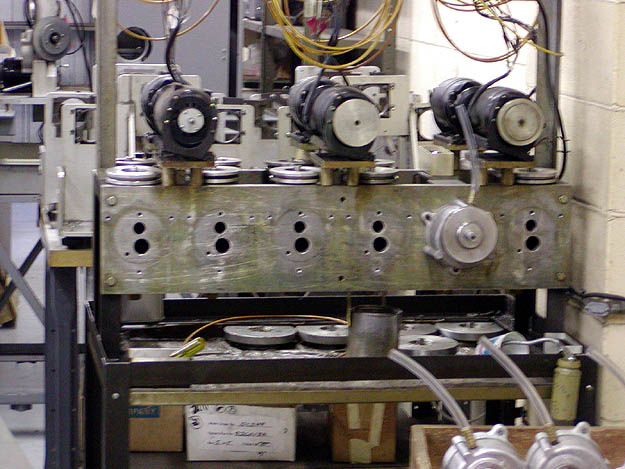

Although more a special venue machine, the Pro 35 machines are still made as well.

Here, Pro 35 movements are run-in.

Strong’s consoles are also manufactured in the Omaha plant.

All the consoles start out as a black steel frame.

Here a worker assembles one of the frames.

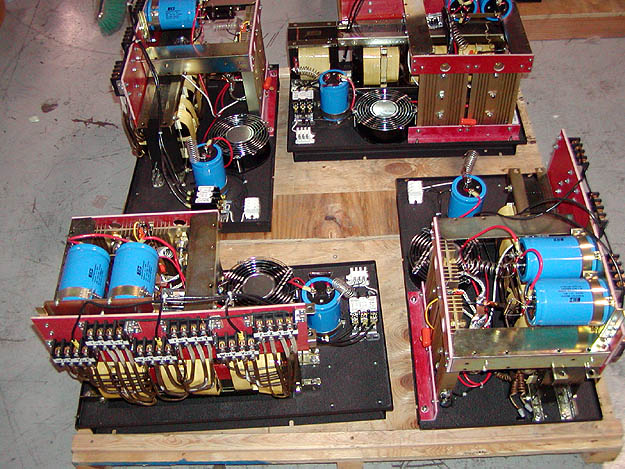

Rectifiers are also put into the console at this stage. Here are a few of the stock units.

After the consoles are assembled, they can be combined with a projection

system and prewired before leaving the factory.

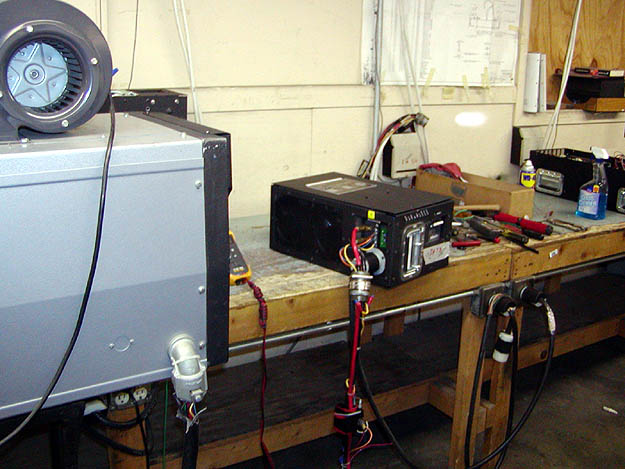

The infamous switching power supplies are also made at Strong, as well as the repairs. This is where all the dead switchers go.

According to one of the engineers, transistor failure accounts for most of the power supply deaths.

All power supplies are tested before they are released. Notice that can of WD-40?

Strong has also diversified in recent years. Here, road construction signs are manufactured.

Despite the hot Nebraska weather the crew remained, shall I say, energetic?

Strong has managed to put food equipment, lighting and two projection

divisions, plus engineering and office areas in a build roughly the size

of a K-Mart. A thank you from Josh and Paul for the tour.

Special thanks to Josh Jones and Paul G. Thompson for the pics.